Europe and progress

The Belgian company Allaeys built the first picking machines in compact form

by Christoph Pinzl

The brothers Pierre and André Allaeys-Dupont were not even 30 years old when they took over the engineering company “Allaeys Constructie Werkhuis” from their father in the early 1950s. In Poperinge, Flanders, not far from the French border, Hector Allaeys had already built hop sprayers and hop drying plants before the war. Unlike these, hop-picking machines from Allaeys also found their way to Germany from 1957 onwards. The agricultural machinery dealer Jakob Deml from Attenkirchen in the Hallertau had heard of the Belgian designers, traveled to Poperinge and secured the first machine with the name “Standard” for operation in Germany. It was to do service at Josef Maier-Krafft in Au i.d. Hallertau, who was not only a hop farmer but also a writer and thus a man for unusual approaches. Jakob Deml was similarly creative in soliciting further customers for the not entirely cheap machine. He, too, had a second profession: hop merchant. He offered the ‘Standard’ to interested growers in return for hop supply contracts. The hop gold rush year of 1957, with fantasy high prices of up to 2,000 marks per hundredweight of hops, served as an argumentation aid.

Allaeys ‘Standard’ machines arrive in Wolnzach by rail in 1960.

In contrast to the English Bruff and Rotobank machines, Allaeys models arrived in their entirety by rail from Belgium, albeit disassembled into individual parts. The necessary know-how was also on board. Allaeys sent its own mechanics along. Together with the helpers of the German dealers, they took over the installation and maintenance on site, above all general agent Karl Wallner from Wolnzach. The men had an enormous job to do in the early years. A hop farmer who had grudgingly purchased such a machine at great expense demanded that it run reliably in time for the harvest. If not, a remedy was needed immediately. On the other hand, the Allaeys brothers only had the few harvest weeks in the year to try it out. Accordingly, not everything went according to plan in the beginning. Night shifts for the mechanics were the norm. At daybreak, the machines were supposed to be back on the job again. In Wolnzach, the German-Belgian contact developed into an intensive partnership with the town of Poperinge, which continues to this day. So picking machines also reaped unexpected rewards.

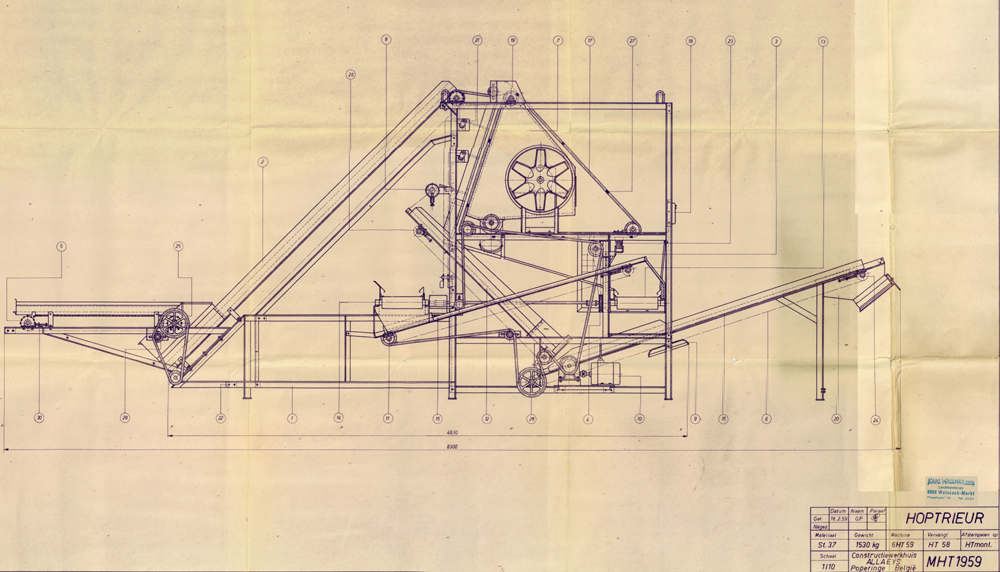

Construction plan for type ‘Standard’

Like all models of the early years, the ‘Standard’ struggled with the fact that its dimensions were not really standard. With its price of around 30,000 marks, its length of around 15 meters including cleaner and a staff requirement of 20 men or women, it was somewhat smaller than the huge Bruff machines from England. Ultimately, however, it had been pre-developed for the market of the many small and medium-sized Bavarian ones.

No wonder that the Allaeys successor model ‘Junior’, which was launched on the German market in 1960, immediately sold extremely well. For the first time, the picker and cleaner were integrated into a single unit – the first compact machine to gain acceptance on the market.

In the fall of 1960, Allaeys presented the final quantum leap in picking machines. The ‘Europa’ model already set the tone in its name. In 1958, the Belgian and European capital of Brussels had built the Atomium, a landmark for an age that had devoted itself entirely to modernization, rationality and technology. Already at that time, the Allaeys company had confidently participated in the World Exhibition in Brussels with a ‘Standard’ small model. This model can still be admired today in the Popering Hop Museum. The ‘Europa’ was finally supposed to put an end to the old ways of picking machines.

Type ‘Europa’ 1963 in the Allaeys construction hall in Poperinge

Its main innovations were above all the long vine pull-out arm with automatic vine ejection and the distinctive slanted vine pull-through. This and a large number of other improvements helped to finally achieve what was actually the aim of the picking machines: to reduce the number of personnel. Whereas with a Bruff there were easily up to 50 helpers around the machine, now just five people were needed to operate the machine, no more. When it turned out that the ‘Europa’ even exceeded the factory’s stated output of up to 400 vines per hour, the speed of the machine was curtly reduced during the first demonstrations so as not to scare off the targeted mid-sized farmer clientele. The following model with the again speaking name ‘Compact’ (more…) developed then to the Allaeys success model par excellence. General representative Karl Wallner told retrospectively that he hardly dared to go to the Wolnzacher folk festival at that time in order not to be besieged by hop farmers willing to buy.

But the Poperingers’ luck gradually ran out. With the Wolf company in the Hallertau town of Geisenfeld, they now faced a competitor that they could not cope with in the long run. After the picking machine business had waned, the Allaeys brothers switched to building car washes in the 1980s. But here too, despite good technology, there was no lasting success. At the beginning of the 1990s, it was all over for the tradition-rich company.

The picking machine model in the Poperinge Hop Museum

During a last visit to Poperinge in 2002 – his brother André had already passed away at that time – Pierre Allaeys and his family received us with great warmth. As a reminder of the old days, the metal front door of the modern 1960s house still shone in the classic Allaeys orange. We were allowed to take with us whatever material had survived from the time of the picking machines. Among them were some of the plans that Pierre had once drawn of his machines by hand, just like an old-school engineer. Some of these plans were over 3 meters long. Today they can be admired in a showcase in the German Hop Museum. Soon, one of the last Allaeys machines still in existence will be on display in the newly built show depot. In working order, of course.